Soil compaction and building roads takes planning, preparation and the use of specialized grading and compacting equipment. Ideally, you want a smooth, uniform surface that can handle heavy loads and heavy weather without breaking up.

Whether you're planning to build a short stretch of road on a smallholding or a network of gravel roads covering a large area, there are a few soil compaction tips and basic rules to follow for a long lasting road.

-

Before you start the construction process, consider the types of vehicles that will be using the road. This will help determine the ideal path and width of the road, as well as the required depth of the base material.

For example, a gravel road that must support heavy-duty commercial vehicles has to be straighter, with less curves and switchbacks, to accommodate the limited maneuverability of these comparatively cumbersome vehicles.

Of course, it also has to be much tougher than a road that's likely to see only light vehicles and comparatively low traffic.

Placing a New Lift of Soil Material

- When placing a new lift of soil material, spread material over the entire area uniformly. Avoid placing soils that have excessively high moisture content. Spread the material with a slow-moving dozer and shape the appropriate profile. Do not bury saturated layers with new materials.

- The easiest way to achieve a stable foundation is to mix a binding agent, such as cement, calcium chloride, salt or lime, into the soil using a stabilizing machine.

- Immediately after spreading is complete, compact the soil starting from outside and working toward the middle of the area.

-

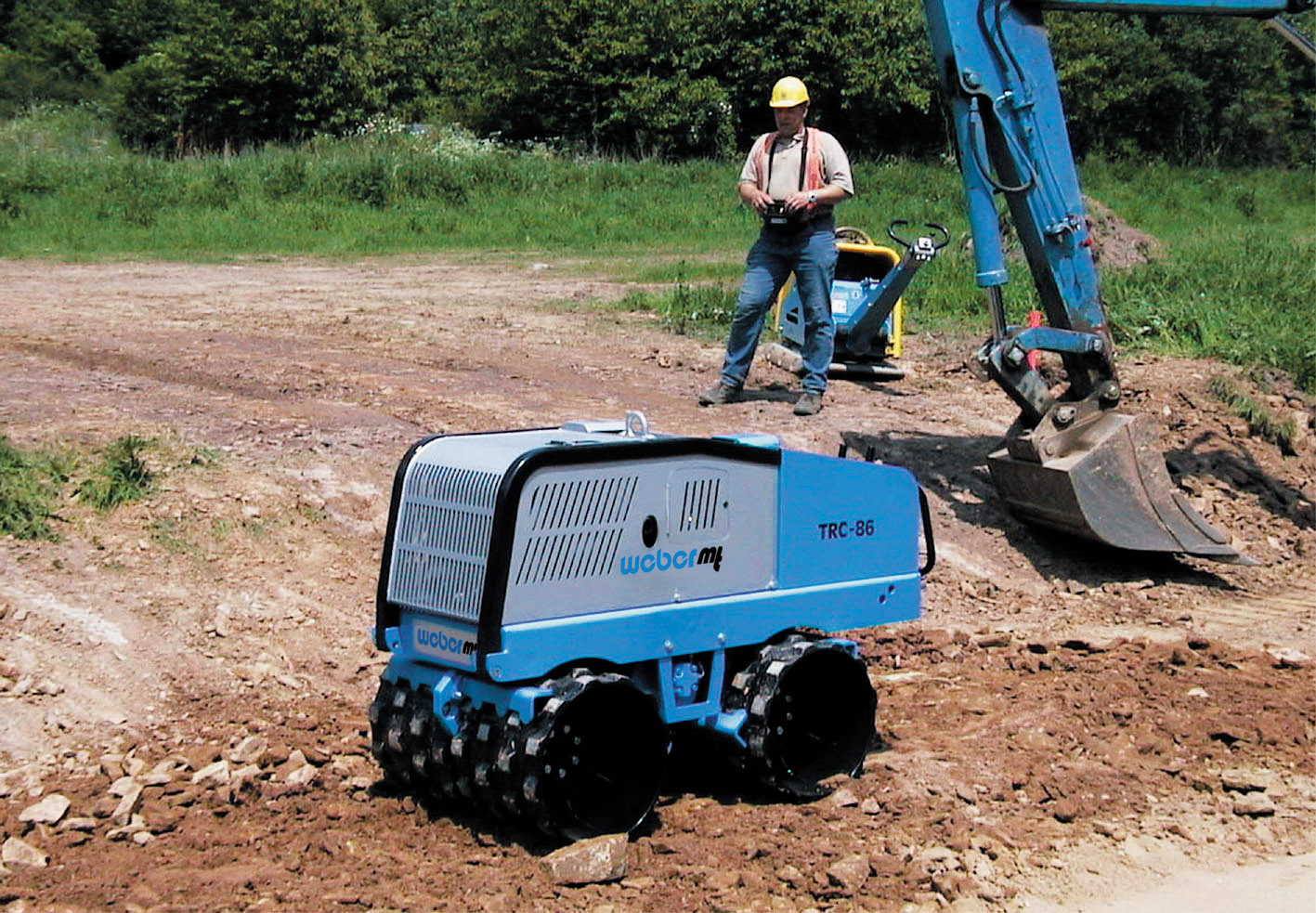

Use the right equipment! Different types of compaction equipment are available—rammers, forward/reversible plates, walk-behind rollers, ride-on rollers and trench rollers.

Rammers and trench rollers are best utilized on cohesive soils, while forward/reversible plates, walk-behind rollers and ride-on rollers are better suited for granular soils.

- Allow the base and binder layers to harden and settle before the final surface layer is applied.

- Fix any surface cavities or areas with visible segregation by adding well-graded material of the same composition.

- Embankment/shoulder areas must be compacted as well; compact the shoulder from the outside edges and work toward the middle areas. Smooth and seal the surface.

- Hire an experienced machine operator. Getting things just right can take an operator many years of practice.

Weather Factors in Soil Compaction

- When working with materials that are susceptible to weather, all placed soil should have a side slope of about 6% to prevent the accumulation of surface water.

-

When poor weather occurs, compact each lift by working a single drum width strip until it is fully compact. Then move over to the next strip, repeating the process and working your way across the lift until the entire area has been compacted.

Be sure to smooth and seal the surface at the end of the day to prevent further water penetration.

- When compacting a flexible base, it is advantageous to use low amplitude with high frequency if the base is adequately rigid. Use high amplitude and medium-to-low frequency when the base is being compacted together with the first lift.

- Use a combination of static and vibratory compaction—vibratory first followed by static.

- If you make too many passes in one direction, you can overcompact the soil. Train your operators to follow proper compaction methods, which will help prevent overcompaction.

-

Before starting trench work, make sure that someone knowledgeable about OSHA requirements inspects the excavation site daily before each shift, and as needed throughout the shift.

When possible, use remote control compaction equipment to protect your workers from cave-ins and falling objects.

- Apply a surface strengthening solution. If you want a gravel road to remain smooth and free of cracks, ruts and potholes, a one-off application of a bituminous surface treatment (BST) may be the answer. This is designed to provide a hard, all-weather, water-resistant surface.

Most importantly, choose quality compaction equipment!

Compaction is the first step to road building, so the last thing you want is a reduction in time and productivity because the equipment is acting up.

Also, poor compaction can result in settlement of the soil. This creates future maintenance issues or, in extreme cases, causes complete structural failure such as cracking, buckling or bulging.

For more information or to rent a soil compaction machine, call us at 855.483.2500!